Organised by Kallman Worldwide, this year’s USA Partnership Pavilion at the Paris Airshow will come to life in a brand-new hall 3 – the first bespoke venue built for the 2024 Summer Olympics. Aerospace Manufacturing previews some of the companies showcasing their products within the pavilion.

Kallman Worldwide creates unique opportunities for US companies to strengthen business relationships around the world by maximising their impact at international tradeshows. This year, the US industry anticipates its largest ever presence at the Paris Airshow.

Guaranteeing that it’s almost always the first company name in any list, we begin our Paris Airshow exhibitor roundup with Aalberts Surface Technologies (hall 3, stand AB174), a leader in heat treatment technologies, services, and solutions and a one-stop shop for complete post-processing solutions for mission-critical parts. Services include stress relief, EDM, Hot Isostatic Pressing (HIP), heat treat and vacuum brazing. Aalberts nickel-brazes honeycomb seals, blades, and vanes for OEM and repair, as well as heat exchangers and fuel delivery system assemblies.

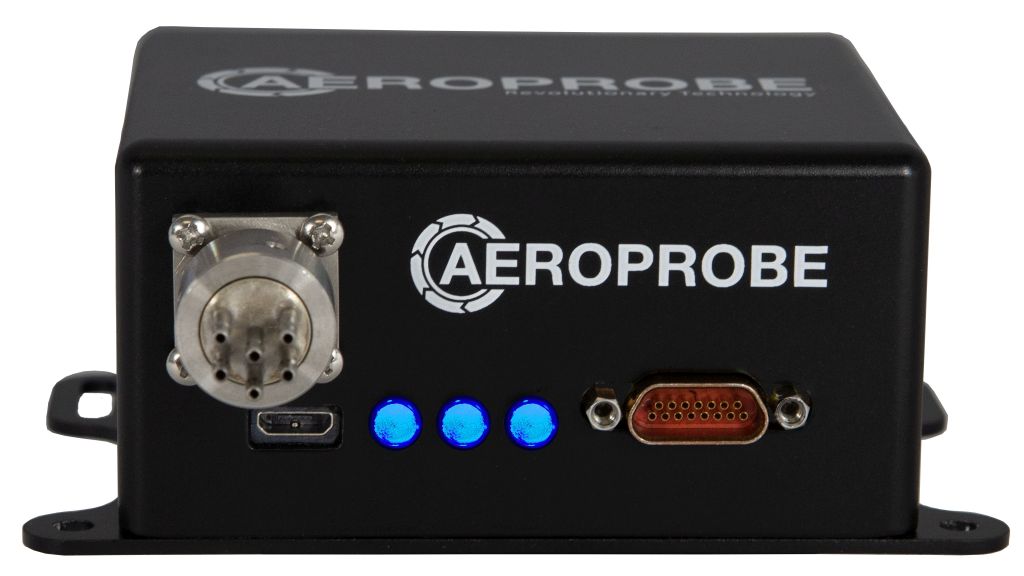

Aeroprobe (hall 3, stand DE162), a leading innovator in air data and flow measurement systems will showcase its new fourth generation Micro Air Data Computers (μADCs) during the Airshow. At the event, Aeroprobe’s booth will not only feature the company’s μADCs, but also feature multi-function air data probes and pitot-static probes.

Aimtek (hall 3, stand G173) manufactures aerospace grade welding wire, brazing alloys, pre-sintered braze preforms, thermal spray materials and equipment, and resistance microwelding equipment, such as ball-tack and honeycomb tack welding. Aimtek is celebrating its 50th anniversary this year.

As a leader in deep-drawn and electroformed components and assemblies, Alpha Metalcraft Group (hall 3, stand G191) says its customers rely on it for aerospace engine and exhaust components, as well as rotor blade and missile components. The company’s advanced processes and experienced team can achieve aggressive schedules and cost targets for everything from prototype products to high-volume production runs.

According to the Alabama Department of Commerce (hall 3, stand DE148), Alabama has a rich history in aerospace and aviation. The state has provided a steady launchpad for companies and organisations involved in flight. Top aerospace industry companies have long had a major presence in Alabama. Boeing and Lockheed Martin, for instance, have been active in Alabama for six decades. Airbus manufactures A220 and A320 family aircraft in Alabama and is now adding a third final assembly line at its Mobile site.

Aviation Repair Technologies (hall 3, stand DE194) is an FAA and EASA-certified repair station specialised in component MRO, airframe maintenance, aircraft storage and disassembly/end-of-life management, parts sales, and logistics for the most popular commercial aircraft operating today. ART supports operators around the world from its MRO facility located at the Arkansas International Airport in Blytheville.

Avtrac (hall 3, stand F194) provides technical services and continuing airworthiness management for lessors and operators. As part of its offerings, the company provides access to the only patented, maintenance-free ignition mitigation means available. INVICTA by Jetaire is designed to bring aircraft into compliance with the Fuel Tank Flammability Reduction Rule by disrupting the fire by reducing the amount of fuel vapor present in in the centre wing tank.

Cadence Aerospace (hall 3, stand AB148) specialises in the machining of complex to ultra-complex geometries with two autonomous businesses, Cadence Aerostructures and Cadence Engine Systems. The company provides flight critical components for commercial, business jet and defence platforms.

Cadence Design Systems (hall 3, stand D203) helps customers design futureproofed electronic systems, on budget, on schedule, sustainable, and adaptable. Cadence’s solutions offer a proven electronic, aerodynamic, and propulsion system design for mission-critical systems. Cadence provides the tools and the semiconductor IP for optimised chip implementation, digital and custom implementation, and advanced system design and verification.

Caylym (hall 3A, stand B192) will showcase its Guardian system, a proven and effective Containerised Aerial Fire Fighting System (CAFFS) that has been deployed and fighting wildfires in the EU since 2015. The destructive environmental effects of wildfires are devastating, and leaders at Caylym are confident that the Guardian – which is an eight-ply, continuously wound corrugated container that holds 264 gallons or 1,000ltrs of liquid – is part of the solution to this growing problem.

As the anchor of the United States’ Aerospace Alley, Connecticut (hall 3, stand B162) will showcase its aerospace and component manufacturing industry. The state boasts a rich industrial heritage and a cluster of world-class companies with a diverse range of expertise and services that are integral to the advancement of the aerospace industry domestically and globally.

Cubic Mission and Performance Solutions’ (hall 3, stand F164) SPEAR provides truth in training with a common data model for air combat training. Cubic’s Synthetic Inject to Live LVC Training is the only solution to inject blended constructive and virtual tracks into fighter cockpit displays at an LFE scale. Its P5 Combat Training System is the Air Combat Manoeuvring Instrumentation (ACMI) system that enables new levels of integration between fourth and fifth generation aircraft.

For more than 40 years, Derco (hall 3, stand DE192) has provided logistics and technical support for fixed-wing aircraft. The company offers a suite of fleet management solutions, including spares distribution, logistics solutions, repair and overhaul services and technical solutions. Derco is said to maintain one of the largest and most diversified aircraft spares inventories in the world, including more than 20,000 unique parts in stock.

ERG Aerospace (hall 3, stand FG184B) is a leading manufacturer of open-celled metal, carbon, and ceramic foam. The company is the sole manufacturer of Duocel foam and develop solutions for high performance applications including energy absorbers, thermal shields, closed loop cooling, optical mirrors, heat exchangers, lightweight high-strength structures, filters and more. All of the company’s flight-proven materials are made in the US in its AS9100-certified production facilities.

EWR Radar Systems (hall 3, stand A116) is dedicated to the advancement of weather radar technology through its product line and lifecycle support services. The company pioneered the use of Solid State GaN transmitters in weather radar systems in 2006 with the introduction of the revolutionary E700XD. Today, EWR says it has more Solid State Weather Radar Systems installed globally than any other manufacturer.

Fastener Dimensions, (FDI) (hall 3, stand A157) specialises in both manufacturing and distribution of aerospace fasteners and small machined components. FDI manufacturers bolts, screws, studs, fittings, inserts, nuts, bushings, spacers, and custom parts to print. The company has in-house forging, CNC turning, CNC milling, centerless grinding, thread rolling and a variety of secondary operations, all under one roof.

For 50 years, Forecast International (hall 3, stand B97) has set the standard for defence and aerospace production forecasting and industry analysis. Its expertise continues to serve clients well amidst rapid market changes and dramatic global events so that they can move their business forward with confidence. Forecast International says it welcomes the opportunity to share knowledge, connect with its colleagues and clients, and forge new relationships.

Globe Engineering (hall 3, stand E148) builds quality aircraft components and assemblies for the commercial, defence and general aviation industries. Globe Engineering’s main facility in Wichita, Kansas comprises more than 400,000ft2. Its 80,000ft2 Maize Road facility consists of tube bending and high accuracy CNC machining, while its Sheridan Facility adds 24,000ft2 of finishing space. Its Nadcap-accredited heat treat and penetrant inspection help to keep lead-times down.

Greater Seattle Partners (hall 3, stand B148) says it is working to achieve a more sustainable aerospace future and has announced the following new developments in the past year: The new R&D Centre for Sustainable Aviation Fuels (SAF) at Paine Field; Boeing has just announced the Boeing Cascade Climate Impact Model for public use in Seattle; The largest hydrogen-powered commercial aircraft is being developed in Greater Seattle; Eviation Alice successfully completed its first ï¬ight of its electric aircraft in Washington State; Since its initial flights in 2012, the Boeing ecoDemonstrator programme has accelerated innovation by taking new technologies out of the lab and testing them in an operational environment.

GSE Dynamics (hall 3, stand A191) is a small, woman-owned full-service engineering services and manufacturing company founded in 1971 that has earned the reputation as the ‘go to’ company for complex and challenging structural and mechanical assemblies in a broad variety of military applications. GSE Composites, a subsidiary, is also a recognised leader in the industry. The company maintains two facilities with a combined 87,000ft2 with headquarters in Hauppauge, New York.

Hydronalix (hall 3, stand 120) operates a complete, high-quality production and textile shop. Custom fabric covers, graphics, and embroidery are offered through in-house industrial automated sewing technology. The craftsmanship and materials can produce a large range of products, from aircraft protection and accessories to land and water enhancements. Hydronalix fabric technicians are talented and passionate with many years of experience.

Helibasket (hall 3, stand AB174) designs and manufactures helicopter external load and ground-support equipment products that emphasise quality, safety and logistical advantage. Helibasket delivers high-quality tow bridles, electric long lines and remote tactical hook systems for extreme conditions and rescue devices, including the Heli-Basket. Helibasket equipment supports all branches of the US Military, National Guard, Reserves, and other agencies.

Hover (hall 3, stand B148) is a new company that has developed two low Cost, Size, Weight, and Power (CSWaP) ruggedised airborne computers for applications including, but not limited to those that require FAA or EASA certification. The H2.0 is a single channel computer and the H1.0 is a dual channel computer. They will be showcased for the first time at the Airshow.

The Illinois Department of Commerce and Economic Opportunity (hall 3, stand DE176) will attend the Airshow along with six Illinois co-exhibitors: Clinkenbeard, Clifford Jacobs-IMT Forge, Ergoseal, Kaney Aerospace, Ingenium Technology Inc and Ingenium Aerospace. Illinois is home to a significant aerospace cluster that is mainly concentrated in the Rockford region, which is one of the leading aerospace employment centres in the country.

Ingenium Aerospace (hall 3, stand DE176) is an industry partner that is focused on highly-engineered/high-performance electromechanical motion control products for space, air, land and sea applications. The company thrives with challenging environment, power density, envelope, weight, reliability and safety requirements. Ingenium is an agile and flexible business that can lead, collaborate, integrate or co-develop projects and products.

Jonal Laboratories (hall, stand 3B162) is a custom manufacturer providing design assistance and supplying a broad range of elastomeric products for the aerospace, military, and industrial markets. Products range from standard O-rings to custom designed complex moulded shapes, fabric reinforced seals, thin-walled diaphragms, aerodynamic and platform seals, rubber-to-metal bonding, silicone extrusions, and EMI/RFI shielding products.

Louisiana Economic Development (LED) (hall 3, stand E194) says its FastStart programme has been recognised as the America’s top workforce development programme for 13 consecutive years. LED FastStart plays a critical role in supplying in-state talent through the development of customised classes for specialised training, such as Haas 5-axis CNC machining centres and training curriculum at eleven Louisiana Community and Technical College (LCTC) System campuses.

Mallard Enterprises (hall 3, stand A116) is introducing the runway-independent ME-1A twin turboprop hull-based all-composite amphibious aircraft. The ME-1A utilises efficient aerodynamic design principles and a lightweight composite structure to enhance a safe simple proven platform. The composite airframe will provide the maximum protection from corrosion in harsh operating environments, minimise aircraft empty weight, reduce both hourly and lifecycle maintenance costs and having fewer parts will be more affordable.

MAPP Technologies (hall 3, stand A147), located in Joplin, Missouri, is an OEM machine and fabrication, and MRO aftermarket service company offering complete OEM build-to-print manufacturing services using specialised process capabilities; from raw material through complex CNC milling/turning and grinding, welding, coating, fabrication and assembly, and final inspection. MAPP holds multiple Nadcap accredited special processes, as well as listings on OEM customer approved supplier lists.

Martin Machine (hall 3, stand D162) manufactures custom bushings and components, specialising in a variety of custom bronze bushings and bronze components. With its machining expertise and latest CNC turn/mill machines, the company offers complete manufacturing of custom precision bearings and bushings, flanges, washers, double flange bearings, full-half bearings, spacers, special and standard oil groove bushings, and custom machined parts.

MELD Manufacturing (hall 3, stand DE162) will showcase its 3PO hybrid machine during the event. The patented technology enables the production of large-scale, fully-dense metal parts without melting the metal, significantly reducing material waste and production time. This approach allows for the creation of complex, high-performance components that meet, and exceed, the stringent requirements of the aerospace sector. Combining additive and subtractive manufacturing capabilities, the 3PO hybrid machine enhances design flexibility and streamlines production processes.

Metal Finishing Company (hall 3, stand E148) is the largest family-owned aerospace processing facility in North America and the only one to also provide heat treatment services. The company has over 450 full-time employees, with over 600,000ft2 of process area, 46 paint stations, 15 wet processing lines and offers over 100 aerospace finishing and pre-finish disciplines. MFC currently holds 17 Nadcap accreditations companywide for chemical processing, NDT, heat treatment, and surface enhancement.

Murphy and Nolan (hall 3, stand FG178) is an AS9100-certified raw material of stainless, alloy, aluminium, and speciality bar and tubing. The company offers cutting, deburring, hardness, electro-conductivity, and XRF testing on site, and can offer centreless grinding, heat treatment, UT inspection, planing, and more through its qualified partners.

The North American Centre of Excellence for Transportation Equipment (NAmTrans) (hall 3, stand A167) is a subsidiary of the North Country Chamber of Commerce located in Plattsburgh, New York. NAmTrans serves the large, growing, and diverse cluster of over 55 transportation equipment and aerospace manufacturers in the seven county North Country Region of New York State. NAmTrans has developed several free, specialised services to help companies navigate entering the US market.

NanoFlowX (hall 3, stand A120) says its coatings can be applied in as little as two steps and two minutes with no masking required. NanoFlowX also provides custom coatings that ensure optimal protection against weatherisation and the adverse impacts of humidity, corrosion, dust, water damage, and even EMI/EMF interference. By selecting NanoFlowX, companies can rest assured that their valuable electronics will be protected by NanoFlowX’s advanced coatings, effectively averting potential failures and safeguarding against the need for expensive repairs, maintenance, and replacements down the line.

Natrion (Startup) has patented and developed a proprietary battery component for electric vehicles (EVs) called the Lithium Solid Ionic Composite (LISIC). LISIC is a solid-state electrolyte membrane that can be implemented rapidly and at high volume on current lithium battery gigafactory production lines to produce solid-state batteries with significantly improved safety and performance as compared to current state-of-the-art liquid-using batteries.

Northrop Grumman (USA Pavilion C22) is a provider of key weapon systems integration, battle management and advanced manufacturing capabilities. The company is at the forefront of advanced manufacturing, responsible for the manufacture of critical elements of the world’s most advanced aircraft. Northrop Grumman creates and integrates the weapon systems essential to air superiority, providing sustainment, modernisation and full lifecycle management.

NWI Aerostructures (hall 3, stand F148) says it continues to build on a strong foundation of delivering quality, complex machined aluminium components, sub-assemblies, and major assemblies for wing structures. Core competencies include machining of medium and long components, forming of long and large parts, large scale processing, automated assembly of structural components, and integrated assembly of major aerospace structures.

Nycote (hall 3, stand AB192) has recently expanded its product line with new materials including: Nycote 99, a next generation anticorrosion coating with updated chemicals; Nysafe, an anti-viral coating for aircraft cabins interiors effective against SARS CoV-2 and compliant with the FST requirements of FAR 25.853; Nyform, a conformal coating for aerospace electronics and TraceSafe a machine readable coating with a tailor made unique fingerprint for anti-counterfeit and traceability applications.

Oklahoma Department of Commerce (hall 3, stand F194) says the state is home to the two largest MRO operations in the world – the American Airlines Maintenance and Engineering Centre, and the Oklahoma City Air Logistics Complex at Tinker Air Force Base. Oklahoma will also showcase its aerospace manufacturing capabilities with the presence of Kratos Defense & Security Solutions which celebrated the production of their 100th drone produced at its Oklahoma City facility.

Park Aerospace (hall 3, stand F148) develops and manufactures hot-melt advanced composite materials used to produce composite structures for the aerospace market. The company designs and fabricates composite parts, structures and assemblies and low volume tooling for the aerospace industry. It also offers an array of prepreg materials designed for hand lay-up or automated fibre placement manufacturing applications, film adhesive materials, and lightning strike protection materials.

PTI Technologies (hall 3, stand 3C148) provides filtration manifolds and filter elements, as well as fluid control products. PTI provides solutions for all fluids including hydraulic, fuel, lube, coolants, air and water. At the Airshow, PTI will highlight technologies for sustainability including advanced air filtration for fuel cells, filtration for thermal management systems and high temperature metal fibre filtration for next generation engines.

RecruitAERO (hall 3, stand E148) is a fractional recruitment and consulting agency set to showcase a new, cost-effective hiring model that’s helping companies stay ahead in a competitive labour market. As the go-to resource for recruiting direct hires, aerospace and defence companies of all sizes have already embraced its services to secure top talent and drive their organisational growth. With a team of highly trained recruiters and cutting-edge technology in place, the company says it delivers unparalleled results.

Renton Coil Spring Company (hall 3, stand B148) is a supplier of springs and spring assemblies to the aviation, space, and defence industries. Renton has the capability and experience to provide spring and wire form solutions for nearly all aerospace needs. Renton works with a wide variety of materials including several stainless steel, Inconel and titanium alloys.

Rite-Kem (hall 3, stand A116) manufacturers products from deck wash for aircraft carriers to dishwashing liquid, including a line of all-natural products. The company also distributes over 4,000 products from other manufacturers. Rite-Kem sells its products locally, online through its own e-commerce website, on Amazon, and through multiple government contracts.

Sciaky (hall 3, stand F180) is a worldwide leader in industrial metal 3D printing and electron beam welding solutions. All of Sciaky’s systems combine CAD, EB directed energy deposition, and layer-additive processing. Starting with a 3D model from a CAD program, Sciaky’s EB gun deposits metal via wire feedstock in successive layers until the part reaches near-net shape. Each system’s vacuum chamber ensures the highest part integrity, while the EB gun maximises material deposition rates by a range of 7 to 40lbs of metal per hour, which is said to be the fastest and most efficient metal deposition process on the market.

ScioTeq (hall 3, stand AB162) develops mission-critical advanced visualisation and computing solutions for the avionics, defence and security and ATC markets. At the Airshow, ScioTeq will showcase several of its avionics display solutions as well as launching its next generation Display Computing Platform, the PU-5200. The PU-5200 is built on the latest SoC technology and offers integrated multi-core CPU and GPU capabilities combined with a wide range of avionics interfaces and compatible with the MOSArt open software platform.

Since 1994, Sigma Aerospace Metals (hall 3, stand F174) has been known in the aerospace and defence industries as a top-rated supplier of aluminium, stainless, titanium, carbon and alloy steels. The company has now extended its line of offerings, including a new facility in the Philadelphia metropolitan, specialising in the processing of PH-grade stainless steel. It has also expanded its cutting capability to handle material ranging from 0.1875”-23” thick and up to 60” in width and 155” in length.

Solar Atmospheres (hall 3, stand G185) provides commercial vacuum heat treating and brazing services. With over 70 vacuum furnaces from lab sized to 48ft long with 150,000lbs capacity, Solar Atmospheres can handle any sized job. Solar operates plants in Eastern and Western Pennsylvania, California, South Carolina, and Michigan. Solar Atmospheres is ISO9001, AS9100, and Nadcap registered for heat treating at all five locations and has a full line of major aerospace prime approvals.

The Texas Pavilion (hall 3, stand A120) will showcase the Lone Star State’s strengths in the aerospace and aviation industry. The state is an epicentre for industry activity, from aircraft and component manufacturing, to MRO, and from aerospace research and new technology and software, to military aircraft development and space exploration. Participating Texas companies include: 14bis Supply Tracking, Aereos Defense, Andrews Aerospace, Aerospace Quality Research & Development, Green Taxi, JANA, Killdeer Mountain Manufacturing, Knight Aerospace, NANCo Aero, NanoflowX, RAM and Venus Aerospace.

United Performance Metals (hall 3, stand C174) offers an extensive inventory of titanium, nickel alloys, stainless steel and cobalt alloy products in a variety of forms with both DFARS and non-DFARS designations. It offers multiple FIRSTCUT+ Processing Services and carries all relevant industry approvals including AS9100D with ISO9001:2015 and array of OEM approvals including LCS.

US Aluminum Castings (USAC) (hall 3, stand B148) is a precision aluminium casting foundry providing green sand, permanent and no-bake moulding services worldwide to the aerospace, military and defence industries. Its team will discuss its precision aluminium castings and services provided. USAC looks forward to meeting with those interested in casting design and production and how it can help support existing and future programmes.

VACCO Industries (hall 3, stand CD148) specialises in the design and production of engineered fluid controls for space and defence markets for more than 65 years, including proven propulsion valves, regulators, filters, couplings, refuelling mechanisms, welded manifolds, and micro propulsion systems for satellite applications, as well as critical quiet valves and manifolds for submarine platforms. Reliable heritage for intelligent solutions.

Valcor Engineering (hall 3, stand FG189) is a provider of precision fluid and motion controls. Its products are designed for demanding environmental conditions. Valcor produces: motor operated valves, solenoid valves, check valves, relief valves, pressure regulators, accumulators, manifolds, and small Electric brakes and clutches for aviation applications.

Vibrac Precision Test Systems (hall 3, A116) will present its high-resolution Bearing Inspector Systems and highly accurate Torque Transducers. The 3100 Bearing Inspector is used to measure the torque characteristics of low friction bearings and bearing assemblies non-destructively at a low speed and high resolution.

VPT (hall 3, stand DE162) is a global leader in providing power conversion solutions for use in avionics, military, and space applications. VPT’s DC-DC converters, EMI filters, accessory products, and engineering services power systems for organisations and programmes. For military programmes that require high-reliability, VPT’s DV Series of isolated DC-DC converters and point-of-load converters are the right choice for critical power systems. VPT’s COTS DC-DC converters deliver the high reliability needed, with designs meeting the requirements of commercial avionics and military applications, including unmanned systems.